If you are a

customer from

UNITED STATES,

click below.

BUY NOW!

|

If you are a

customer from

CANADA,

click below.

BUY NOW!

|

FRC - Fiber Reinforced Composite

The use of fiber reinforced composites (FRC) has entrenched itself in dentistry, like many other industries, due to the physical advantages that FRC have over the metals that have been used historically, be it stainless steel, chrome cobalt, or titanium. FRC combine a very high tensile strength with a low modulus of elasticity making them ideal to resist the repetitive stress forces seen intra orally. Glass fiber posts, like the BIOLIGHT® line of posts, have become the new standard for pre-fabricated endodontic posts due to their physical strength and high level of physical compatibility with tooth structure. FiBER FORCE® rope and mesh fibers have proven themselves to be very effective at reinforcing dentures and other intra-oral appliances, far more so than metals.

Comparative Graph of Physical Properties

| MATERIAL |

TENSILE STRENGTH (MPa) |

YOUNG'S ELASTIC MODULUS (GPa) |

| E-Glass |

2000 |

80 |

| Steel |

531 |

200 |

| Titanium alloy |

900 |

105-120 |

| Stainless steel |

860 |

195 |

| Chrome - Cobalt |

750 |

225 |

| Chrome - Nickel |

570 |

170 |

| Enamel |

10 |

100 |

| Dentin |

100 |

20 |

| Cortical Bone |

170 |

20 |

| PMMA |

70 |

6 |

Physical Properties

CST® fibers are made of e-glass and UDMA resin. This strong matrix allows the fiber matrix to chemically bond with the acrylic or composite materials into which the fibers are integrated. Unlike metal, which can in some cases weaken the acrylic or composite into which it is integrated, the net result is a real reinforcement and improvement in the resistance to stress forces of the final appliance. Internal data shows that acrylic reinforced with fiber mesh, for example, is 2.5 times (150%) more resistant to a repeated stress before showing any signs of damage than acrylic reinforced with metal mesh.

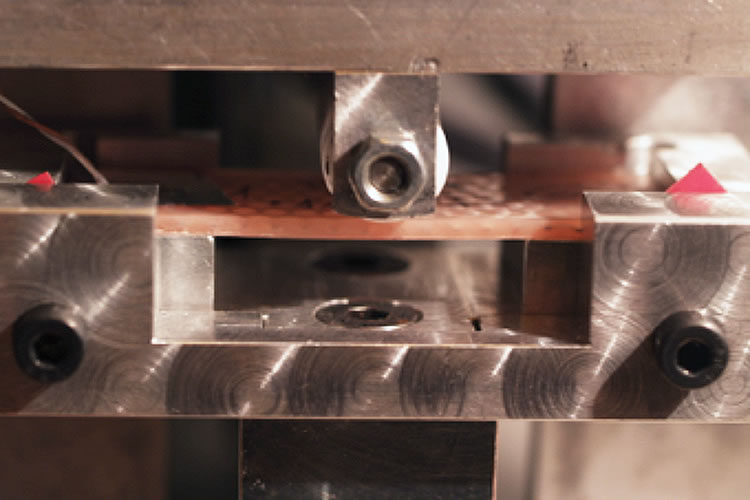

Innovative Fiber Design

CST® fibers are specially designed for extra toughness and strength. Traditional glass fibers strands come in either a braided format or a uni-directional (UD) format. The innovation with CST® fibers is a combined UD-Braided construction which maximizes physical strength and maintains positive handling characteristics - we call them hybrid compressible fibers. CST® hybrid compressible fibers have 330% more tensile strength than traditional braided fiber rope of a similar dimension and volume. Tensile strength is a key component in determining a materials overall resistance to stress forces.

Fracture Resistance

Testing

[1] of the CST® concept demonstrates that CST® implant frameworks are 1.65 times stronger than frameworks with no reinforcement when subjected to an increasing three-point load. They also compare well with titanium frameworks and show a greater resistance to stress forces before the acrylic starts to show signs of de-cohesion. This validates the impacts and benefits of the fibers and acrylic working together and resulting in a more natural distribution of stress forces across and within the mass of the appliance.

Three-Point Load Fracture Test Results: Load to Failure

|

Unreinforced samples |

Titanium bar |

CST® reinforced |

| Acrylic decohesion |

245 |

337 |

405 |

| Acrylic fracture |

301 |

454 |

405 |

Three-Point Load Fracture Test Results: Load to Failure

Results in decaNewtons (daN)

It's interesting to note that in all three groups tested (unreinforced, titanium and CST®) the amount of force required to create damage to the acrylic far exceeded even the greatest amount of force that can be applied in the posterior portion of the mouth - 50 dNA.[2] All the results taken together suggests that problems that are seen intra-orally with fixed/removable hybrid dentures are more related to the acrylic fatiguing and weakening over time and/or the incompatibility of the acrylic with the metal sub-structure. CST® offers a solution to both challenges as it truly reinforces the acrylic and is chemically and physically compatible with it.

Distal Extension

While the maximum length of the distal extension for any fixed appliance is still a question of debate and more complex than popular measures such as the A-P spread, there is no debate that the distal extension is an area of concern as it relates to the durability and longevity of an implant-supported appliance appliance, as well as the health of the implants placed.

A study[1] of the durability of the distal extension has demonstrated that a CST® framework will resist a force of 92 daN before acrylic failure - three times or 200% more force than an acrylic-only framework. In this case the distal extension was 11mm, which is the maximum recommended length of the distal extension with a CST® fiber framework.

[1] - Internal testing

[2] - J. F. BATES, G. D. STAFFORD and A. HARRISON. Masticatory function-a review of the literature: (II) Speed of movement of the mandible, rate of chewing and forces developed in chewing. Journal of Oral Rehabilitation, October 1975, Volume 2, Issue 4, 349-361.

If you are a

customer from

UNITED STATES,

click below.

BUY NOW!

|

If you are a

customer from

CANADA,

click below.

BUY NOW!

|