If you are a

customer from

UNITED STATES,

click below.

BUY NOW!

|

If you are a

customer from

CANADA,

click below.

BUY NOW!

|

Technical Properties

- E-glass construction for superior physical properties

- Treated with silane (a bond enhancer) for high bond strength

- Pre-impregnated in an industrial environment for consistently high bond strengths

- Light-curing resins for accurate forming of mesh and reduced processing time

Tensile Strength & Modulus of Elasticity

The attraction of using E-glass material is due to its physical properties. As seen in the table below, E-glass has on one hand a very high tensile strength, yet on the other hand is a relatively elastic material. This is ideal for the type of stress forces seen intra-orally: repetitive forces that place a long-term strain on the appliance. Due to their inherent fatigue resistance FiBER FORCE® reinforcements allow the appliance to stand up to the stresses delivered.

Technical Data

The use of fiber reinforced composites (FRC) has evolved technically to the point that their use is widespread in a wide range of industries: aeronautical, automotive, and marine to name just a few. The physical properties and advantages of FRC are well understood and proven, and the use of these materials is common place. The primary benefits of FRC are their high fracture and fatigue resistance coupled with their light weight.

| MATERIAL |

TENSILE STRENGTH (MPa) |

YOUNG'S ELASTIC MODULUS (GPa) |

| E-Glass |

2000 |

80 |

| Steel |

531 |

200 |

| Titanium alloy |

900 |

105-120 |

| Stainless steel |

860 |

195 |

| Chrome - Cobalt |

750 |

225 |

| Chrome - Nickel |

570 |

170 |

| Enamel |

10 |

100 |

| Dentin |

100 |

20 |

| Cortical Bone |

170 |

20 |

| PMMA |

70 |

6 |

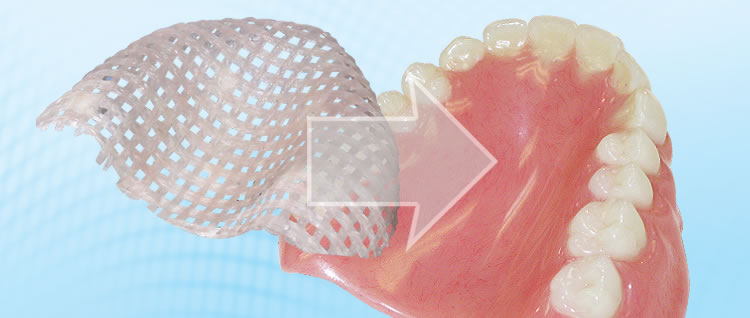

The synergistic way

The overall level of reinforcement is further improved by the synergistic way the FiBER FORCE® and the acrylic/composite work together. With two materials bonded together chemically a "monoblock" is created – making the whole more resistant than the sum of its parts. This monoblock also shares and distributes loads in a more even way, as the FiBER FORCE® and the acrylic/resin have similar elastic properties. Thus the problems created when a very rigid material is simply sandwiched into the acrylic/composite are completely avoided.

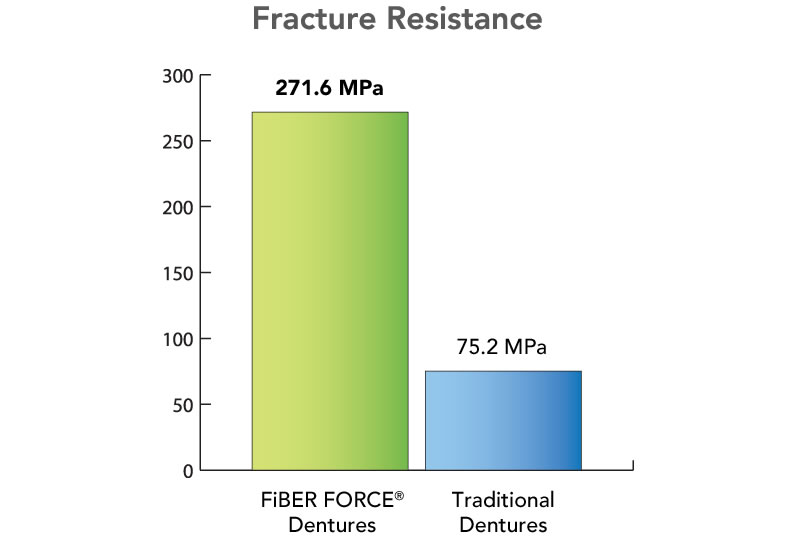

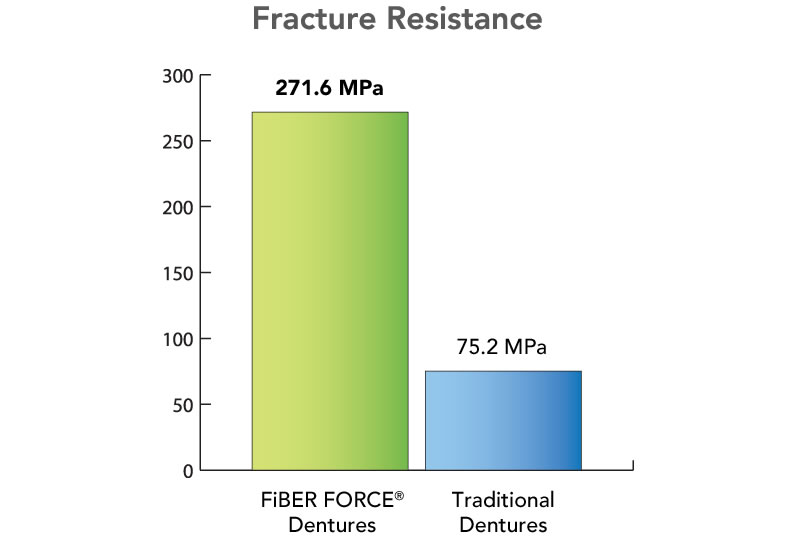

Fracture Resistance

Internal data from the manufacturers of FiBER FORCE® compared the fracture resistance of unreinforced full upper dentures to those reinforced with mesh. Test results showed a 300% increase in fracture resistance with mesh reinforcement.

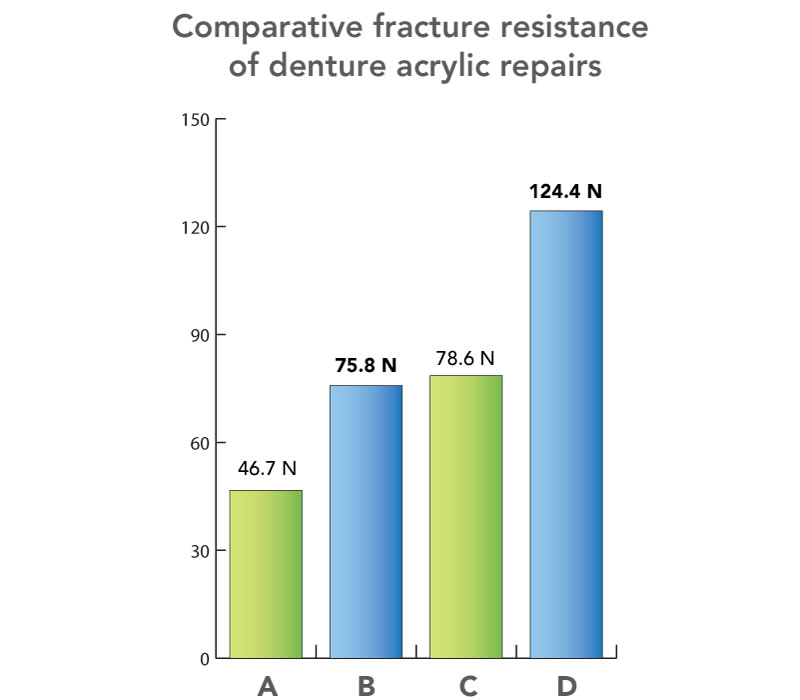

Comparative fracture resistance of denture acrylic repairs

One study that looked at the effect of reinforcing acrylic with E-glass FRC showed that repaired acrylic is never as strong as it was originally. Using E-glass braided fibers returned the repaired acrylic to its original strength, while using UD fibers increased the resistance of the acrylic beyond its original strength.

A |

Repaired denture acrylic without fiber reinforcement |

46.7 N |

B |

Repaired denture acrylic with woven pre-impregnated e-glass fibers |

75.8 N |

C |

Control group (new denture acrylic) |

78.6 N |

D |

Repaired denture acrylic with UD pre-impregnated e-glass fibers |

124.4 N |

Reference:

Kostoulas, I., Kavoura, V., Frangou, M. & Polyzois, L. “Fracture Force, Deflection, and Toughness of Acrylic Denture Repairs Involving Glass Fiber Reinforcement”. Journal of Prosthodontics, 17(4), 257-261.

If you are a

customer from

UNITED STATES,

click below.

BUY NOW!

|

If you are a

customer from

CANADA,

click below.

BUY NOW!

|